Composite materials

High-frequency composite nanostructures consisting of oriented magnetic nanochains and non-magnetic nanoparticles were obtained by simultaneous ablation of magnetic and non- magnetic material at atmospheric pressure in the presence of a magnetic field. Composites made of parallel nanochains (Fe3O4) and noble metal nanoparticles (Ag) exhibit plasmonic properties and sensitivity to light polarization.

Composite materials

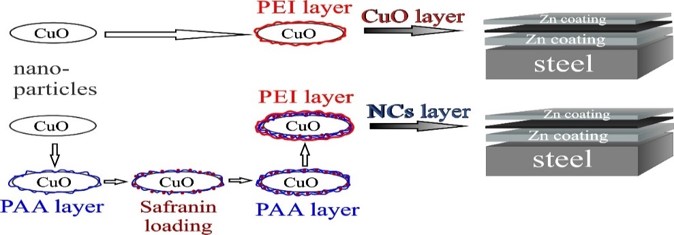

A multifunctional hybrid zinc coating has been developed for the combined protection of low carbon steel against corrosion and biocorrosion in an aggressive chlorine-containing environment. pH-sensitive nanocontainers (NCs) with the corrosion inhibitor Safranin entrapped in the polyacrylic acid (PAA) and polyethyleneimine (PEI) polymer coating of copper oxide (CuO) nanoparticles as a biocide were used. They are embedded as an interlayer in a standard zinc coating on steel (sandwich type structure) by electrophoretic deposition in an aqueous medium to reduce the possibility of CuO dissolution. It has been established that the hybrid coatings improve the corrosion performance of the steel in a model corrosion environment (5% NaCl solution) over a period of 55 days and under external polarization conditions, compared to a single layer zinc coating.

Contact:

krad@issp.bas.bg

Composite materials

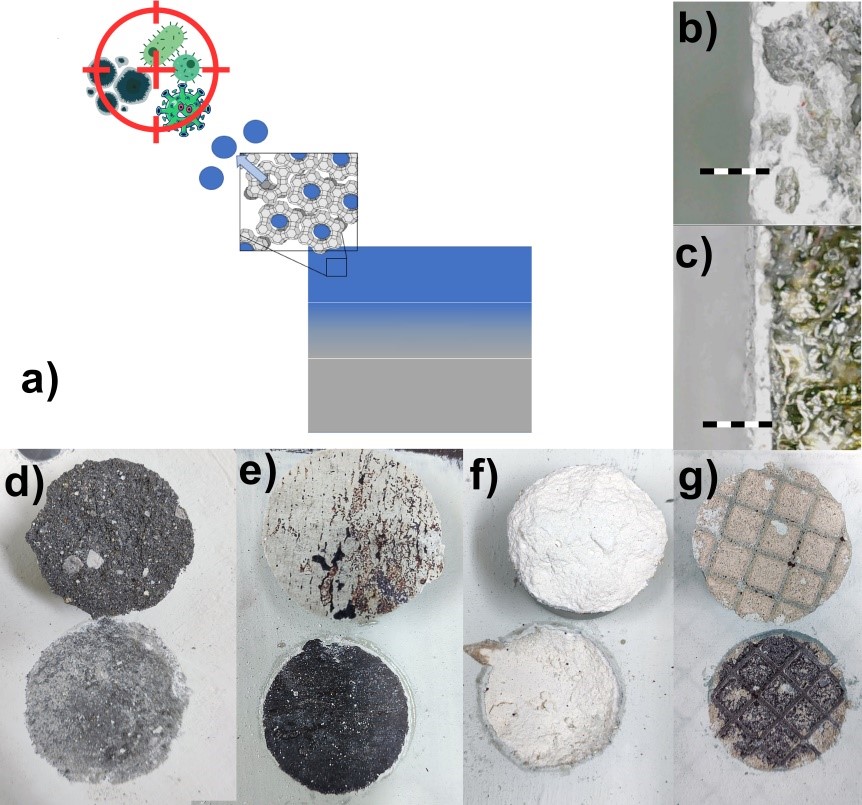

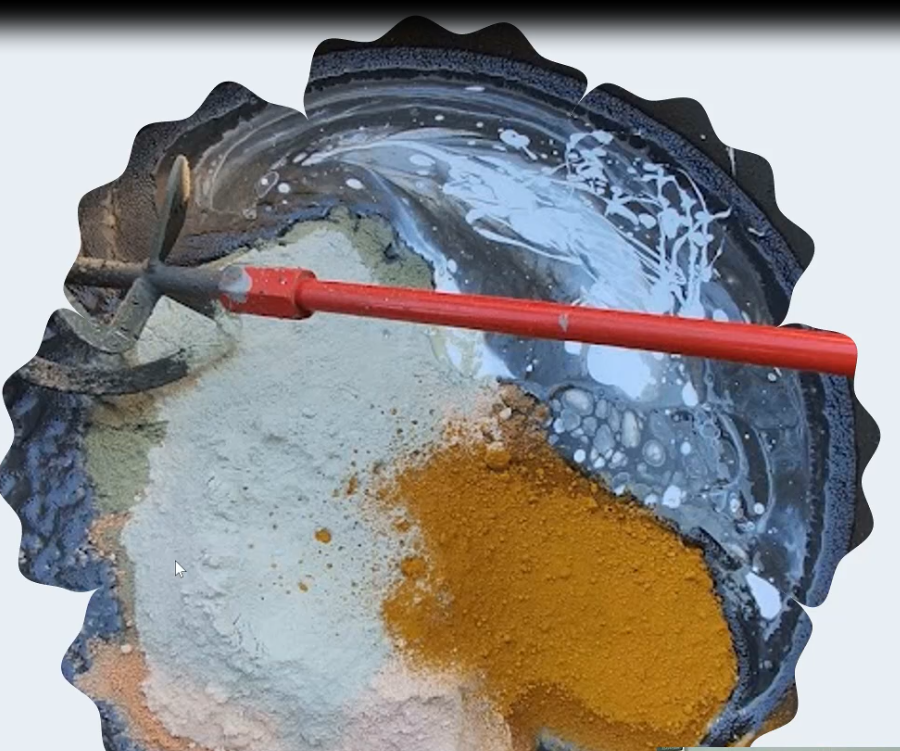

A team of scientists from IMC-BAS has developed new geopolymer paints with long-lasting antimicrobial activity using Ag- and Cu-modified natural zeolite – clinoptilolite. Two types of paints based on TiO2 (GP-TiO2) and ZnO (GP-Zn) were obtained, which were tested on different coatings, and their antimicrobial activity was evaluated by accelerated carbonation of the obtained coatings in a CO2 chamber for 7 days against bacteria, fungi and viruses. The paints also show excellent adhesive properties to various coatings.

Composite materials

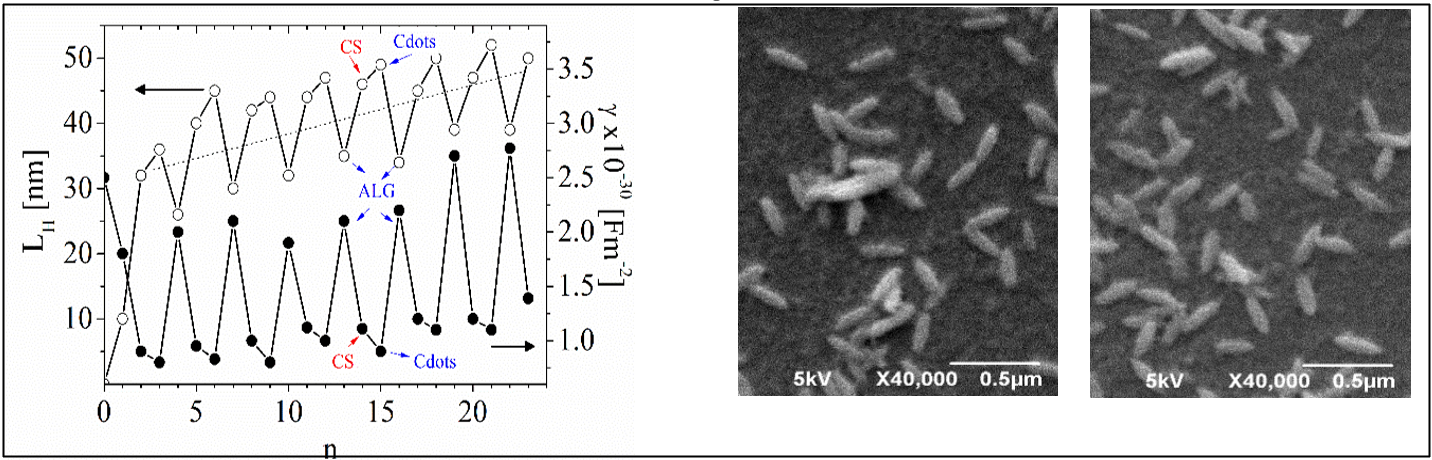

At the Institute of Physical Chemistry – BAS, carbon quantum dots (Cdots) were successfully embedded in a multilayer film of alginate (ALG) and chitosan (CS), formed by successive adsorption on β-FeOOH model particles.

Contact:

office@jic.bas.bg

Composite materials

The Institute of Mineralogy and Crystallography “Acad. Ivan Kostov” presents the development of antimicrobial geopolymer coatings based on natural zeolite.

Geopolymer paints are water-soluble, do not contain volatile organic compounds or other toxic substances, have excellent adhesion to concrete, steel, ceramics, plasterboard and others.

They connect to the base and make a reinforced layer. They are vapor- and gas-permeable, which allows the walls to “breathe”, UV-stable and long-lasting. By using modified zeolite with silver and copper ions, geopolymer paints with antimicrobial properties – antibacterial and antifungal – were obtained.

Suitable for facade and interior solutions, restoration of cultural monuments, prevention of the spread of pathogens – suitable for hospitals, kindergartens, premises in the food industry. Various colors – compatible with oxide paints.

Antimicrobial geopolymer paints can be used as interior paints, countertop coatings, railings, and more.

Composite materials

The Institute for Space Research and Technology at BAS presents a technology for glass carbon coatings on graphite materials designed for extended operation under extreme conditions.

The presented innovative development is the result of using, developing and testing in real space conditions the technology for coating and densifying graphite materials with vitreous carbon (amorphous modification of carbon). This is a joint development of: Institute for Space Research and Technologies – BAS, Institute of Metallurgy – BAS; Institute of Organic Chemistry with Phytochemistry Center – BAS and Institute of General and Inorganic Chemistry of BAS

The originality of the method for obtaining glassy carbon coatings (CV) is based on the specific temperature regimes used when obtaining the starting material and the unique technological processes applied in the subsequent coating of the graphite spherical sensors with CV. The method described above for impregnating and covering graphite and ceramic materials with SV is protected by a copyright certificate in Bulgaria. CB is an amorphous modification of carbon, which is characterized by a certain scheme of arrangement of carbon molecules, in contrast to other modifications of carbon, which are characterized by a crystalline structure. For the practical production of such an amorphous modification of carbon, it is necessary to precisely select the starting material and then subject it to an appropriate heat treatment in vacuum or in an inert atmosphere. The main advantage of the CB coating method used in the fabrication of spherical sensors for electric fields in the Earth’s plasma, compared to the use of monolithic CB, is that the created method allows to adjust the qualities of the CB coatings on the surface of the spherical graphite probes, if after preliminary measurement of their working surfaces in laboratory conditions, it turns out that the value and variations of the separation work for the electron go beyond the defined limits.

The material has multiple applications: from space materials to high-tech medicine, for example: gears; graphite cartridges for pressing and firing carbide inserts for cutting tools; crucibles of different shapes, for melting pure materials; graphite heaters for obtaining ultra-pure materials; orthopedic elements for limb surgery; glass carbon-coated titanium ceramic abutments for vascular surgery, etc.

The technology offered and tested in real space conditions can be used: for future space expeditions to the Moon, Mars and other planets in the Solar System; in space apparatus and other technological equipment requiring stability in the storage of the structural and physicochemical characteristics of glassy carbon coatings; in the conditions of long-term work in outer space, associated with extreme values of temperature changes, high vacuum, cosmic radiation, etc. In addition, it can be used in: the manufacture of heart valves; manufacture of prostheses; scientific and applied activities related to the use of the proposed technology for compaction and coating of graphite materials in the field of future space programs and work in extreme conditions.

Contact:

office@jic.bas.bg