PROCESS MODELING

The convective flow of a viscous incompressible fluid in a vertical channel with transparent walls under the influence of solar radiation has been modeled. The task models the process of heat exchange in the water chambers used in facade glass units with circulating water. The model Navier-Stokes equations and energy have been solved analytically for the case of a bulk heat source generated by the visible and infrared solar spectrum.

PROCESS MODELING

At IE-BAN, a technology has been developed for obtaining electrically conductive traces on the surface of aluminum nitride ceramics with arbitrary geometry and desired resistance. On the basis of such structures, a resistive heater was developed. Al-containing structures have also been applied as active systems for surface-enhanced Raman spectroscopy (SERS) in the ultraviolet region. These results are the basis for developing a new type of structures for SERS with applications in the detection of substances of high social significance.

PROCESS MODELING

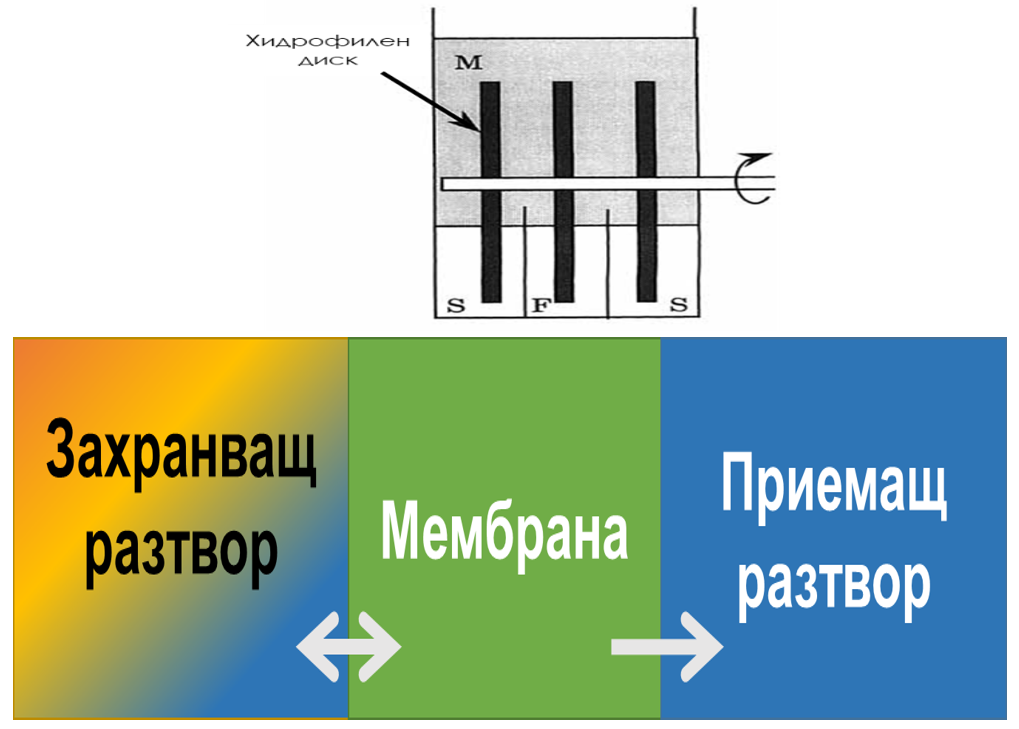

Researchers from the Institute of Chemical Engineering – BAS have developed a method for selective extraction of substances.

Key Features of the Method:

– Continuous Operation: The method allows for uninterrupted processing.

– “Soft” Conditions: It operates under mild conditions.

– Liquid Phase Processing: The process takes place entirely in the liquid phase.

– No Phase Changes: There are no changes in the phase state of the chemical system, which implies low energy consumption.

– High Purity: The resulting product has high purity.

– Use of “Green” Liquid Membranes: It offers possibilities for using environmentally friendly liquid membranes.